Description

Grow film is commonly used to create custom grow sections or rooms, allowing the individual to tailor their growing space to their exact requirements - something that a tent does not allow for.

ORCA Grow Film is made from threads of a high density specialized reflective plastic which are bonded together creating a unique surface topography that is mold and algae growth resistant. The resulting geometry of the microfibers and the submicron pores within the microfiber, create a highly reflective and diffuse surface. The same principal is found in snowflakes, where normally transparent water is transformed into reflective bright white snow through the unique geometry of ice crystal formation.

Specifications

- Size 1.37 m X 10 m

- 28mm thick

- The grow film is water-resistant, washable and cleanable with common household cleaners.

- Recommended use with Orca Seem Tape

- Made in USA

Our opinion:

We always recommend going with Orca film over the traditional reflective foils. Orca Film also found in our bud box tent range.

Features

99% Diffuse Surface:

- ORCA's patent pending white plastic microfiber structure creates even light distribution across material surface regardless of incident angle of light. The resulting isotropic surface luminance eliminates hot spots and does not require surface to be hung flat during installation.

Mold and algae growth resistant.

Highly Reflective Surface:

- 94% reflectivity across the full visible light spectrum, ORCA Grow Film is the highest performing reflective surface in the hydroponic industry.

Thermally Reflecting:

- High infrared reflectance keeps heat and light where it should be. ORCA Grow Film® remains highly reflective at wavelengths out past 700nm.

No Color Shift or Iridescence:

- Light reflected from surface maintains the original color wavelength so you get the full spectrum from your lamps.

Durable:

- Puncture and tear resistant.

UV Protected and Stable:

- Blocks out harmful UV light with wavelength below 400nm; material does not yellow. Some reflective foils reflect light below 400nm, a range that contains UVB rays which can be harmful to plants and their growth.

Recyclable:

- Eco-friendly material containing no halogens, plasticizers or VOCs.

Reflectance vs. Wavelength

The chart below demonstrates the reflectance vs. wavelength performance of several popular brands and materials used in hydroponic grow rooms. Metalized Polyethylene Terephthalate Film was first developed by DuPont in the 1950's; originally branded as Mylar, it is now commonly known as PET film and manufactured all over the world.

Many products in the hydroponic industry are associated with false or misleading performance claims, which is true of reflective films. PET film products are marketed to hydroponic consumers with performance claims as high as 99% reflectivity, despite historically testing in the low to upper 80% reflectance range in the visible spectrum.

ORCA Grow Film incorporates the latest reflective technology from the engineered synthetic materials field, similar to those found in solid-state lighting, flat panel TV's and PDA's.

Testing completed by Orb Optronix

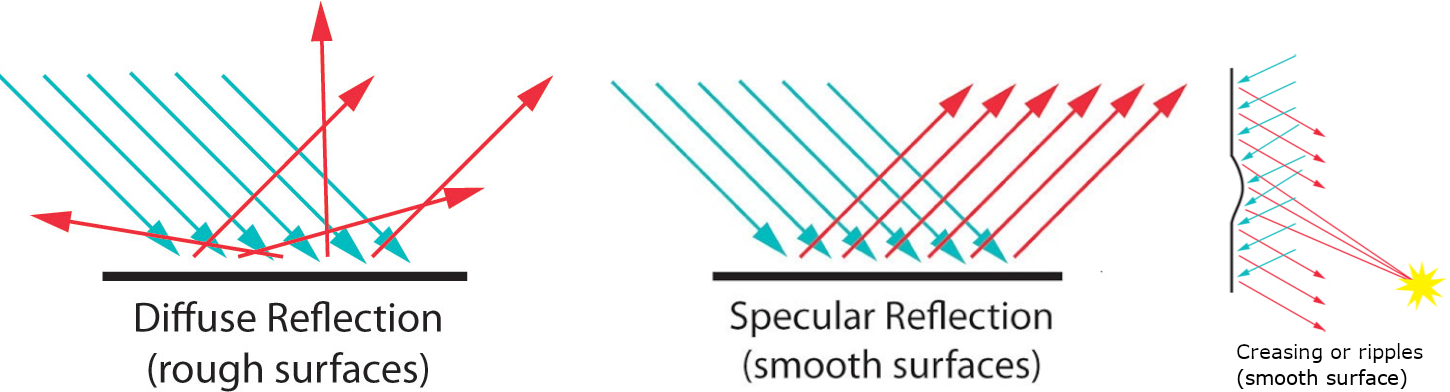

Diffuse vs. Specular reflection

Whether the surface is microscopically rough or smooth has a tremendous impact upon the subsequent reflection of a beam of light.

Specular reflection is the mirror-like reflection of light from a surface, in which light from a single incoming direction (a ray) is reflected into a single outgoing direction. This is in contrast to diffuse reflection, where incoming light is reflected in a broad range of directions. Changes in the orientation of a specular reflective surface(i.e. a crinkle in mylar), can cause concentrated light rays to converge together either on their first or subsequent bounces. Hot spots or flash points occur when the direction of these concentrated light rays converge together.

Reflective foils have naturally smooth surfaces, even at the microscopic level, offering each individual ray of light the same surface orientation. As such, reflective foils are a natural specular reflective material.

The microscopic geometry of ORCA Grow Film microfiber and pore structure provides a rough surface, offering each individual ray of light a different surface orientation. As such, ORCA Grow Film is a natural diffuse reflective material.

Why Diffuse Reflection Matters

Hot spots or flash points occur when bundles of concentrated light rays which are traveling parallel to each other converge. In hydroponic grow rooms, the hot spot phenomenon is dramatically increased when using a material with a specular reflection as a supplementary lighting source to the grow lamps.

A light beam can be thought of as a bundle of individual light rays which are traveling parallel to each other. Each individual light ray of the bundle follows the law of reflection. If the bundle of light rays are incident upon a smooth surface, then the light rays reflect and remain concentrated in a bundle upon leaving the surface.

In a grow room environment, orientation changes are commonly associated with corners and angles where walls, floors, and ceilings meet. Static objects in the grow room like duct work, equipment, tools, and planters can also contribute on subsequent bounces. Regardless of the grow room layout, the use of a specular reflective material on the walls, ceiling, and floors as a supplement lighting device to your grow lamps will be the biggest contributor to hot spots.

Foils produce a specular reflection and therefore need to be hung on a wall with an absolutely flat/smooth orientation. Any creasing or ripples in the material either as a result of installation, or due to manufacturing imperfections, increase changes in the orientation of the specular reflection, causing the concentrated light rays to converge, thus promoting hot spots.

On the other hand, if the surface is microscopically rough, the light rays will reflect and diffuse in many different directions. The microscopic geometry of the ORCA Grow Film microfibers and pores means that each individual ray meets a surface which has a different orientation.

The normal line at the point of incidence is different for different rays. Subsequently, when the individual rays reflect off the rough surface according to the law of reflection, they scatter in different directions. The result is that the rays of light are incident upon the surface in a concentrated bundle and are diffused upon reflection. Not only does a natural diffuse reflecting surface eliminate hot spots, you no longer need to worry about the product being installed on an absolutely flat/smooth orientation. The number and types of corners, angles, static objects found in your grow room layout may still reduce overall efficiency, but the efficiency will be greater because of the improved distribution from subsequent bounces off the reflecting surface. Less hotspots means more efficient utilization of your light.

Some manufacturers attempt to reduce the specular nature of their foil and the resulting hot spots by embossing the foils surface. They “scratch” or “strike” the surface with a diamond pattern to create a surface that is partially rough. While this process creates a partial diffuse effect, it does not change the inherit specular nature of the material, the surface, or the resulting reflected light.

Performance

ORCA Grow Film® is 94% reflective across the full visible spectrum. Which means it averages 94% reflectivity for every individual wavelength across the spectrum that is relevant for plant stimulation.

Reflectance % Measurement, wavelength in the relevant spectrum:

The reflecting characteristics for any given material will be different for each electromagnetic wavelength. A measurement or reflective % for one wavelength is not a relevant indicator for an entire spectrum.

Example of relevant spectrum and measurement:

Why 94% reflectance matters:

Every time a light ray (radiant energy) contacts a surface, a portion of the energy is absorbed and a portion is reflected, but there is no energy loss. Materials that reflect significantly more radiant energy than they absorb are considered reflective. ORCA Grow Film is 94% reflective across the full visible spectrum, or it only absorbs 6% of the radiant energy. Reflective materials are used to increase the overall effective coverage from the grow lights in a grow room. When you cover the walls, ceiling, and floors with a quality reflective material you can increase the overall efficiency of the grow room by 30 to 75 percent.